Add to Cart

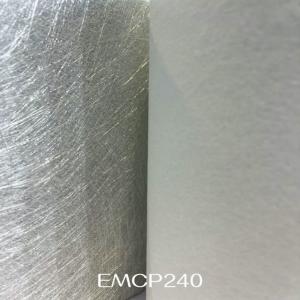

Polyester Veil Combing With Chopped Strand Mat To Cover Glassfiber Veins And Improve Surface Outlook For FRP Products

Polyester veil combo chopped strand mat is a fiber combo felt sheet. When producing chopped strand mat, spread polyester veil on it, then forming with powder bond by high-temperature drying.

Its features:

Application:

Specifications:

| Product NO. |

Overall Weight (g/m2) |

Polyester veil (g/m2) |

Chopped strand Mat (g/m2) |

Width (mm) |

Composite Process |

| EMCP190 | 190 | 40 | 150 | 40-1500 | powder bond |

| EMCP240 | 240 | 40 | 200 | 40-1500 | powder bond |

| EMCP340 | 340 | 40 | 300 | 40-1500 | powder bond |